freeze dried to perfection

Here at Mixologist's Garden, we use hand-selected premium varieties of fruit and berries. They’re individually chosen for their superior quality and ability to maintain flavour and aroma during the freeze-drying process.

Our produce is primarily sourced in Europe, procuring from the largest citrus suppliers in Spain and our berries are mainly sourced from continental Europe.

With our garnish proven to deliver a better taste than fresh, every one of our pouches are designed for easy storage and to elevate every drinking experience.

Our factory certifications

meet the team

-

Marcel

Brand Ambassador/ Founder

Marcel likes to use our Strawberry Slices to enhance his summer ciders -

Rob

Business Development

Rob always uses our orange slices in his Whisky Sours -

Sean

Brand Activation

Sean always uses our Raspberries in his Sidecar cocktails

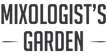

why choose freeze dried fruit?

sustainability efforts

We believe it is vital that we use exclusively sun-ripened fruit which doesn't require any additional resources for growing, not only for the environment but for the quality of our produce.

We hand-select the fruit and control its provenance, ensuring only the finest is chosen. We also significantly contribute to reducing carbon emissions during transportation, as our products are up to 90% lighter than fresh fruit.

-

Less waste than fresh garnishes

-

90% lighter, producing less carbon emissions

-

Fruit is only sourced when it's in season

-

Sourced as locally as possible

the drying process

Using freeze dried garnishes instead of fresh fruits ensures that you maximise on taste and aroma for the best quality drink. Where the texture of fresh fruit tends to change after a while, our freeze dried alternative retains its taste and texture throughout the experience.

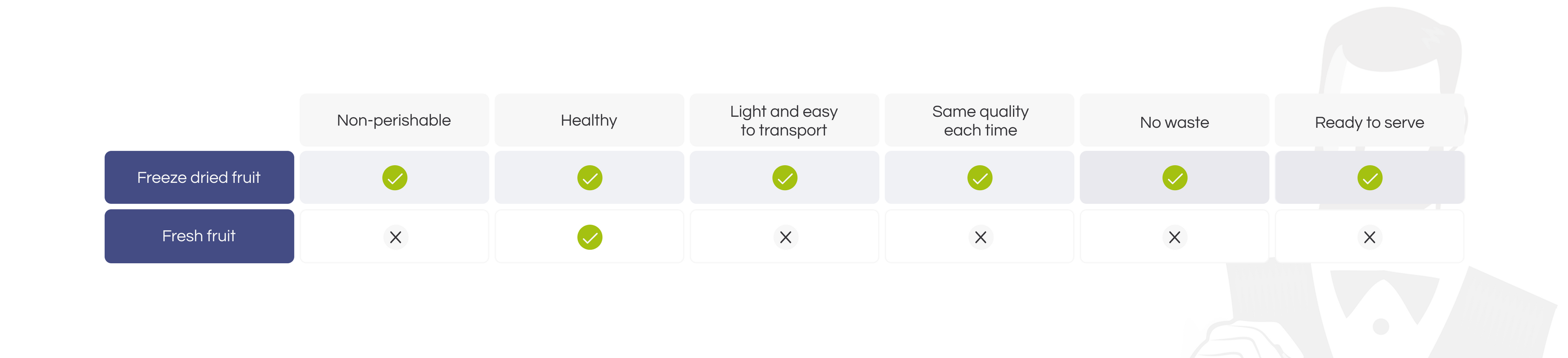

Our fruit is initially quick frozen and kept at -40°C to capture shape and quality. Moisture is then removed in an atmosphere-controlled vacuum at low temperatures, in a process known as sublimation.

-

1: Freezing

Bring the temperature of the product down to -40°C

-

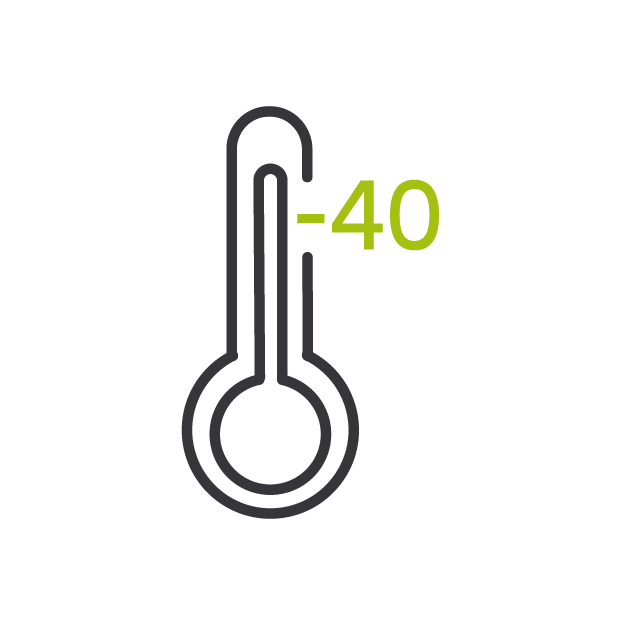

2: Pressure

Reduce the pressure until there's only a vacuum

-

3: Heating

Heat is applied to the frozen product to trigger sublimation

-

4: Vapour collection

The ice changes directly into gas, keeping the fruit's structure

-

5: Final product

The atmospheric pressure is recovered to extract the freeze dried product